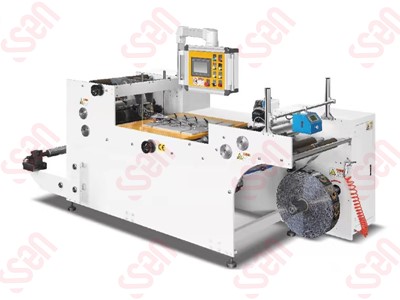

1. Main Features:

-Stable and heavy-duty frame for high speed operation of 400m/min.

-Adjustable forming plate creates efficient operation.

-Auto solvent feeding control.

-Auto tension control for unwind/rewind unit to maintain the optimun tension.

-Accurate product width.

-Cantilevered rewind/unwind shaft for fast roll changeover.

-PLC with color touch screen control system.

-Rewind oscillation control to produce high quality rolls.

-Name brand EPC web guide device, precision±0.1mm

-Copper tubing with felted wool for gluing, work with glue pump (dispenser) and PLC. The PLC can control the glue capacity with speed changes.

-Static eliminator is adopted before rewinder.

-Whole machine with 4 pcs of servo motors(2 for traction, 1 for rewinder, 1 for oscillation), and 1pc magnetic powder brake for unwinder.

-Linear perforation.

-Traditional aluminum plates forming device for sizes from 30-80mm.

-Auto stop when the rolls finish.

2. Main Technical Parameter:

|

DHA-300 |

|

|

Width of Unwinding |

620mm |

|

Diameter of Unwinding |

Ø600mm |

|

Diameter of Rewinding |

Ø700mm |

|

Max.sealing width |

300mm |

|

Min.sealing width |

20mm |

|

Max.machine speed |

450m/min |

|

Max speed of Machine |

450m/min |

|

Voltage of Whole Machine |

380V-50HZ-3PH |

|

Dimension of Machine (L*W*H) |

3000*1600*1720mm |

|

Machinei weight |

1400kgs |

English

English Español

Español русский

русский